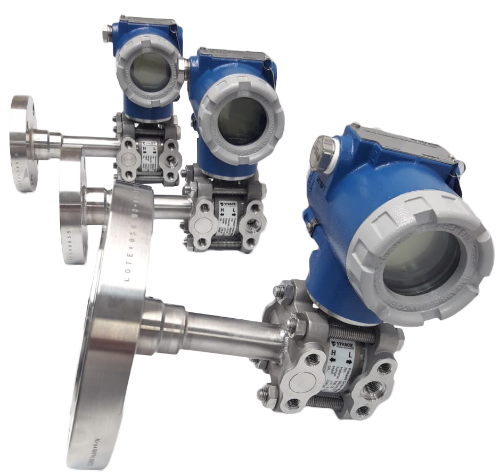

VPT10 is a pressure transmitter with high performance capacitive sensor, designed for differential, absolute and gauge pressure measurements, as well as models for level applications: flanged, remote seal and sanitary options.

The VPT10 is available with HART® 7 and Profibus-PA communication protocols, being a robust and highly reliable solution for pressure, level and flow measurements, ensuring efficient and reliable process results with high availability.

The DTM Libraries for HART and Profibus-PA devices can be found on:

HART Profibus-PA

The remote sensor model offers several installation advantages, especially in industrial applications and hazardous areas. It consists of an indicator unit, with an LCD display and no sensor attached, and a transmitter unit, which houses the pressure sensor. Both units are connected by a communication cable.

Here are some of its main advantages:

These features make remote-sensing pressure transmitters a highly efficient and safe solution for a variety of applications, especially in challenging industrial environments.

| Accuracy | Standard Model: ± 0.075% High Performance Model: ± 0.05% |

| Communication Protocol | HART® 7 and Profibus PA |

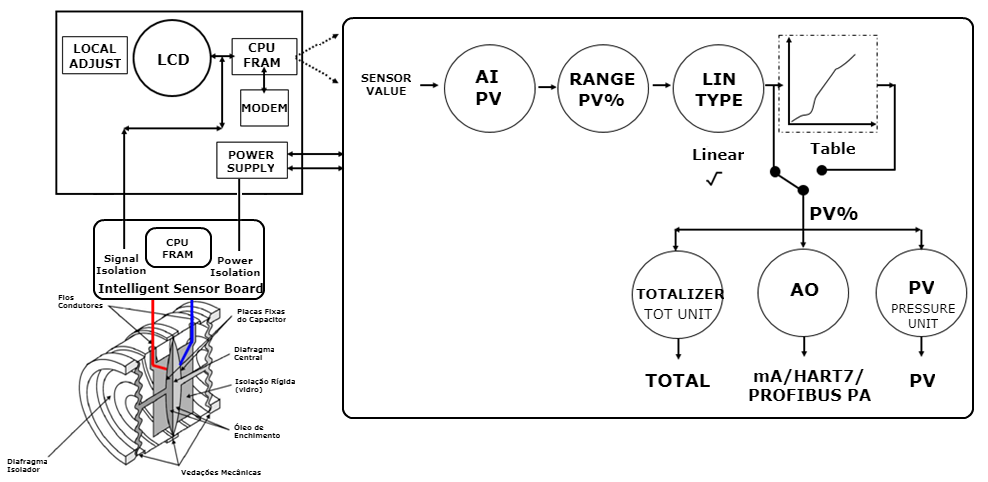

| Sensor Type | Microprocessor capacitive sensor, digital readout and temperature and pressure compensation algorithm |

| Models / Measurement Ranges | D1 / -7.5 to 7.5 kPa (-30 to 30 inH2O) D2 / -37.4 to 37.4 kPa (-150 to 150 inH2O) D3 / -186.8 to 186.8 kPa (-27 to 27 psi) D4 / -690 to 690 kPa (-100 to 100 psi) D5 / -2068 to 2068 kPa (-300 to 300 psi) D6 / -6890 to 6890 kPa (-1000 to 1000 psi) M1 / -7.5 to 7.5 kPa (-30 to 30 inH2O) M2 / -37.4 to 37.4 kPa (-150 to 150 inH2O) M3 / -100 to 186.8 kPa (-14.7 to 27 psi) M4 / -100 to 690 kPa (-14.7 to 100 psi) M5 / -100 to 2068 kPa (-14.7 to 300 psi) M6 / -100 to 6890 kPa (-14.7 to 1000 psi) M7 / -0.1 to 20.68 MPa (-14.7 to 3000 psi) A2 / 0 to 37.4 (0 to 150 inH2O) A3 / 0 to 186.8 kPa (0 to 27 psi) A4 / 0 to 690 kPa (0 to 100 psi) A5 / 0 to 2068 kPa (0 to 300 psi) A6 / 0 to 6890 kPa (0 to 1000 psi) H2 / -37.4 to 37.4 kPa (-150 to 150 inH2O) H3 / -186.8 to 186.8 kPa (-27 to 27 psi) H4 / -690 to 690 kPa (-100 to 100 psi) H5 / -2068 to 2068 kPa (-300 to 300 psi) |

| Static Pressure and Overpressure Limits | Ranges 1 to 5: 13 MPa (1885 psi) Range 6: 15.5 MPa (2250 psi) Range 7: 46.5 MPa (6740 psi) |

| Stability* | Standard template: ± 0.2% URL (5 years) High performance model: ± 0.2% URL (15 years) * For ±20 °C temperature changes, 0-100% relative humidity, up to 7 MPa (70 bar) line pressure, installation according to best practices and proper assembly for processes in which hydrogen atoms may be generated (hydrogen migration). |

| Rangeability | 150:1 or 200:1 (depending on model) |

| Response Time | 50 ms |

| Output Types | Linear, Square Root and Table |

| Temperature Limits | Ambient : -40 to 85 °C Process: -40 to 100 °C Storage: -40 to 100 °C |

| Humidity Limits | 0 to 100% RH (Relative Humidity) |

| Configuration | Remote configuration through tools based on EDDL, FDT / DTM, as well as Android platform. Local configuration via magnetic key. |

| Write Protection | For hardware and software with an indicative on-screen icon |

| Totalization | Volumetric and non-volatile mass flow |

| Certification in Classified Area | Explosion-Proof and Intrinsically Safe |

| Degree of Protection | IP67 |

| Mounting | In the field, with pipe support Ø 2” |

| Housing Material | Aluminum |

| Approximate Weight with Bracket | 4 kg |

Main Benefits:

• Basic Accuracy: ± 0.075%

• High Accuracy: ± 0.05%

• Innovative: High Performance Microprocessor Capacitive Sensor, digital reading

• Built-in Temperature and Pressure Compensation

• Range 1: -765 to 765 mmH2O up to Range 7: -1 to 210 Kgf/cm2

• HART® 7 / 4-20mA and PROFIBUS-PA

• Totalizing with Persistence

• Square Root Extraction and User Table

• 5 Digit LCD, Rotatable, Multifunctional and Easy to Use

• Advanced Diagnostics

• Supports DD, EDDL and FDT / DTM

• No Power Polarity

• Built-in Transient Protector

• Low ETP-Probable Total Error

• High Rangeability and Stability

• Local Adjustment with Magnetic Tool